Chillers' Plant Manager

The ChallengeMajor amounts of power is being consumed into cooling spaces.

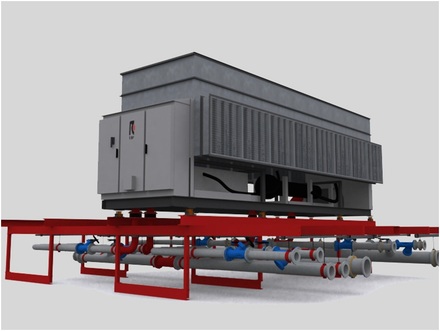

Having no efficient control over the chillers’ plant can cost you extreme amounts of money being drained into electricity bills as well as into maintenance of their equipments. The chilled water plant typically consists of one or more chillers usually provided by a plant manager (either communicating or non-communicating) that is measuring its internal parameters. These chillers are providing the needed cooling to the water coming from the load and provided back with the required set point achieved and via several primary, secondary, and perhaps tertiary pumps. The chillers are responsible for about 65% of the total consumption of the chilled water plant. They are the source of extreme maintenance headaches without mentioning their major capital cost which impose a very hard decision to make when a replacement is required. On the other hand, the chilled water pumps are also responsible for a major amounts of avoidable power waste due to the constant speed running, maintenance issues, and minimum circuit pressure requirement. Intelligent control of the chilled water management plant is a process that needs to take various electrical and mechanical considerations and make them all work to achieve the maximum efficient operation granting the comfort levels needed with minimum overheads. The SolutionSatchnet solution for chillers plant management deploy high-tech controllers and instrumentation to pull out the complex operational logic that would guarantee an optimized operation that pays attention to every little detail of your chilled water plant including:

|

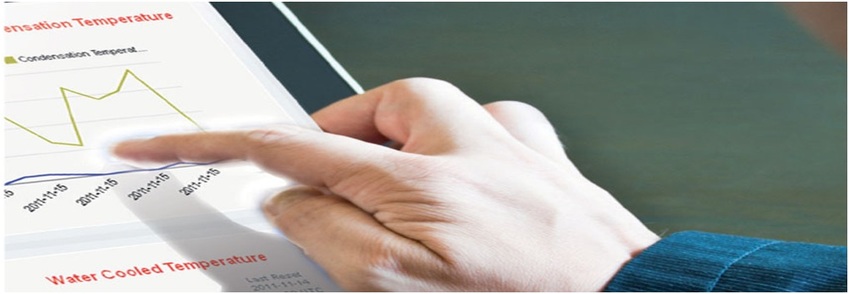

The solution has considered your need to be in control and thus it provides all functionalities that you’d ever need to enhance the plant performance and significantly reduce your overall power consumption, these functionalities include:

The intelligent system proposes a support to all three open protocols most known in the industry (BACnet, LON, and Modbus) and thus provide communication flexibility like never before, which means that integration is no longer an issue. Furthermore, the supported web services also is setting the intelligence up high for easy remote management from anywhere or to even use weather data and temperature forecasts from the web to set the operational scheme ahead. All proposed controllers are freely programmable for ultimate flexibility in delivering complex logic and setting the operation parameters. and finally, this architecture also allows for open communication with your BMS system either existing, or yet to exist. |